Magnetic stripes

Magnetic stripes

The mid 1950s saw the expansion in the use of magnetic-optical projection systems and the increased demand from television for film with magnetic sound. This was achieved by adding a thin stripe of magnetic material along one side of the film. Two methods of applying the stripe appeared to have been in commercial use.

- A liquid coating, supplied in bulk by the manufacturer, was applied with a precision application nozzle in a thin stripe down the side of the film. A more robust bond was made if the film was vacuum treated to compact and permanently shrink the gelatin emulsion.

- An adhesive tape laminating process developed by 3M. In this process an adhesive tape carrying the magnetic layer and a stripping layer is laminated to the film base. The acrylate type adhesive required both heat and pressure to adhere to the film. Once the adhesive has been attached to the emulsion the stripping film layer is removed leaving the magnetic material permanently in place.

Over time the striped magnetic coating can lift from the film leading to the loss of the audio component. Fortunately the magnetic stripe often remained intact. This project was to look at the modes of failure of the adhesion of the stripe and to develop a technique for readhering the stripe to the film restoring the audio component.

The examples examined so far in this project have used the later method, the adhesive tape.

Modes of failure

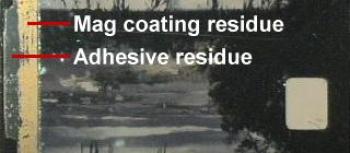

The most common area of failure has been the magnetic binder to adhesive layer. The adhesives appear to be very robust with good adhesion to the film. To a lesser extent the binders hold together well, although there may be some irregular separation of the binder near the adhesive layer.

Readhering the stripe

To readhere the stripe to the adhesive layer a technique using Methyl Ethyl Ketone (MEK)* to partially soften the binder and possibly the adhesive layer was found to be the most successful method. Working over short sections, about 25mm at a time, the MEK is brushed onto the adhesive with a small paintbrush taking care not to work the surface too hard otherwise the adhesive and any binder residue would lift making the final stripe uneven in height. After the MEK is applied the stripe is carefuly realigned the original distance in from the edge of the film. Slight pressure is applied to the stripe for a few seconds before the next section is worked on. Care is needed to prevent undue stretching of the stripe.

While the adhesion of the readhered stripe is relatively strong it is possible to remove the stripe. Care in handling the repaired film is essential.

**Methyl Ethyl Ketone requires careful handling.* Obtain and study a relevant Material Safety Data Sheet before using.

Further Work

Examples of the other method of applying stripe, the liquid coating process, need to be found and a determination of the modes of failure and techniques to readhere the stripe developed.

References

- SMPTE Journal Vol 64 No:7 July 1955 – Laboratory 16mm Film Striping Unit

- SMPTE Journal Vol 64 No:7 July 1955 – Recent Developments in Magnetic Striping by the Lamination Process

- SMPTE Journal Vol 73 No:3 March 1964 – A Note on a Simplified Striping Technique

The National Film and Sound Archive of Australia acknowledges Australia’s Aboriginal and Torres Strait Islander peoples as the Traditional Custodians of the land on which we work and live and gives respect to their Elders both past and present.