Conservation treatment

Conservation treatment

Before attempting any treatment, a thorough assessment of the film’s condition and stability needs to be made.

Some treatments, especially those using aqueous solutions, will damage unstable emulsions and bases.

Cleaning

Dirt and grease accumulate on the emulsion and base of a film through handling and static electrical charge. Dirt is not only a nuisance in blemishing the projected image but can cause physical damage during handling and can contain chemicals that will accelerate deterioration of the image or film base.

Spot cleaning

As the name implies this is treating an individual spot of dirt or grease. The technique involves carefully working at the dirt, grease or tape adhesive residue with a cotton bud that is liberally wetted with a suitable solvent (not water!). Work from the edge of the spot towards the centre as this tends to leave less residue to deal with.

All safety precautions such as good ventilation and protective equipment must be adhered to.

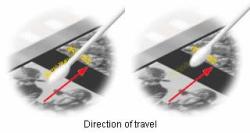

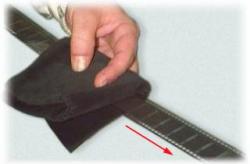

Dry dust back

The simplest method of treating a whole roll of film is the 'dry dust back’. This uses a soft velvet cloth made from either cotton or polyester. Before using, check that the cloth is free from dirt of any sort. Holding the clean cloth gently with the fingers as shown in Fig 12.2, wind the film carefully through. The cloth should be rearranged frequently so that a fresh, clean portion is being used.

This method is only suitable for very light dirt and requires great care not to scratch the film.

After using the cloth, wash it with a mild, non-perfumed soap and ensure that it is thoroughly dry before using it next.

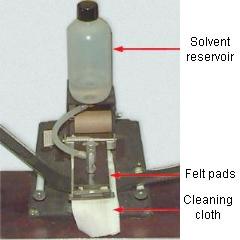

Wet dust back

It is possible to use a dust back cloth dampened with some cleaning solvent. However, this is not recommended due to OH&S concerns.

There are available cleaning machines that work in the same manner as wet dusting back, such as the ECO Film Cleaner shown in Fig 12.3. These machines use felt pads to supply solvent to the cleaning cloths. The cloths are replaced regularly, depending on how dirty the film is.

All the precautions to ensure the safety of the film and the person working on the film regarding ventilation and protective equipment must be followed.

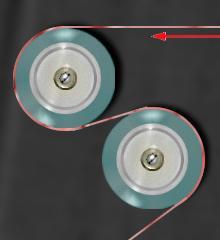

Particle transfer rollers

Particle Transfer Roller (PTR) cleaners use a slightly sticky urethane coated roller that the dust particles adhere to as the film is wound across them. At least two rollers are required, one for each side of the film, though four rollers are often used. PTR are really only suitable for loose dirt, such as film dust, and have little or no effect on grease or dirt trapped by grease.

The film wraps at least halfway around each roller to maximise the surface contact (Fig 12.5). Due to the tacky nature of the PTR surface there is a great deal of tension applied to the film as it is wound over the rollers. Consequently film should be immediately rewound at a lower tension if the film is to be returned to storage

The rollers are washed with soap and water then dried and are ready for use again.

PTR cleaners should not be used with films with flaking emulsion as the adhesive is sufficiently strong to lift the emulsion off the base. If the film being cleaned was decomposing then the rollers should be washed before using on non decomposing films.

Solvents

Organic solvents (hydrocarbons)

The most common and efficient way of cleaning films has been by using a solvent system. For the last 20 years or so 1,1,1 trichloroethane ('Genklene’) has been used, but because of concerns over depletion of the upper atmosphere ozone layer, it has been banned from manufacture. The most popular replacement solvent, perchloroethylene, is not as efficient a cleaner and has a greater need for vapour containment as it poses a health and safety risk.

Many other solvents that have been used for cleaning have significant drawbacks. Flammability is one such problem. Alcohols, such as ethanol, may be used for some cleaning applications but can be harmful to the film by dissolving plasticisers from the film base or adversely affecting the image forming dyes.

New solvents, such as 3M’s fluoroethers or HFE series, are very safe to use from a staff point of view, but tend to be less efficient cleaners and are currently very expensive.

| Solvent | Efficiency |

|---|---|

| Perchloroethylene (Perc, Tetrachloroethylene) | Good |

| HFE 7100 (3M) Methyl Nonafluorobutyl ether/Methyl Nonafluoroisobutyl ether | Adequate |

| HFE 7200 (3M) Ethyl Perfluoroisobutyl ether/ Ethyl Perfluorobutyl ether | Adequate |

| HFC 43-10 mee (DUPONT) (1,1,1,2,3,4,4,5,5,5-decafluoro Pentane) | Adequate |

| ASAHI KLIN AK-225 (ASAHI) (3,3-dichloro-1,1,1,2,2-pentafluoropropane) | Good |

| ISOPROPANOL (2-propanol, secondary propyl alcohol, dimethyl carbinol, petrohol) | Good |

| ISOBUTYLBENZENE (2-methylpropyl benzene, methyl-1-phenylpropane) | Good |

| ACTREL 1064 L (EXXON) (Mixture of hydrocarbons) | Good |

| Hydrotreated Naptha (Signal Inc.) Hydrocarbon Type Film Cleaner 40 | Excellent |

| Isopar® G Naptha Exxon Chemical | Excellent |

| Exxsol® D3135 Naptha Exxon Chemical | Excellent |

| Soltrol® 100 Phillips Chemical | Excellent |

Table 12.1 Suitable solvents — from the Kodak Website (www.KODAK.com)

Aqueous (water)

Water combined with mild surfactants has some uses in film cleaning. There are some drawbacks with using aqueous systems with archival films. As cellulose ester film bases decompose the generated acid alters the solubility of the gelatin emulsion. Even the short exposure used in film cleaning applications can be sufficient to fully wet the emulsion. Gelatin can absorb water at a very fast rate and can be fully wetted in around three seconds. Once the pH of gelatin shifts beyond the iso-electric point the uptake of water is dramatically increased.

Ultrasonic cleaning

Ultrasonic cleaners are efficient at removing a low level of dirt, oil and grease.

The film is transported through a tank of slightly heated solvent. Ultrasonic transducers are fitted to the outside of the tank and pulse sound waves at 20 KHz through the tank.

In air and most solids there is a continuous transition as the wave passes through. In most liquids there is continuous transition as long as the amplitude of the sound is relatively low.

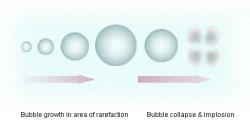

As the amplitude increases the negative pressure in the area of rarefaction (that follows immediately behind the wavefront) becomes so great that the liquid can fracture or 'tear’. This phenomenon is known as 'cavitation’. Cavitation results in 'bubbles’ developing in the liquid. As successive waves pass through the liquid the bubbles oscillate and eventually grow to an unstable size and then collapse and finally implode violently (Fig 12.6).

The implosion causes shock waves to be radiated through the liquid. It is the shock from the continuous imploding bubbles that moves the solvent around the tank. The constant movement provides a continuous supply of fresh solvent to attack the dirt.

Like all mechanised film transport equipment frequent maintenance is required to ensure that the films are not damaged during use.

Dirt adhering to rollers and incorrectly positioned jets or air knives can scratch the film. If the machine is fitted with air knives to remove the solvent as the film emerges from the cleaning tank these must be correctly aligned to ensure that the solvent is removed cleanly from the film surface and there are no streaks.

Regular maintenance also includes recovery of the cleaning solvent and replacement of the filters. Water separators and pH adjustment systems also need to be regularly checked.

The transport mechanism is relatively uncontrolled in terms of tension and the films are taken up at a very high tension. Prior to return to storage films must be rewound to a lower tension.

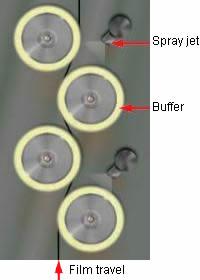

The buffer cleaning method is very efficient. It is able to remove more deeply embedded dirt and a greater amount of old and sticky oil than film cleaners that use ultrasonics only.

The buffer process is very gentle, partially due to the soft nature of the buffers and partially to the constant spray of solvent that is applied to the buffers flushing away the dirt.

The rollers must be regularly checked that there is no dirt trapped in the buffer. Using some unwanted film run a 'scratch test’ at start up and examine the film carfully for any signs of scratching. A strong directional light is good for examining the test for scratches.

Regular maintenance — especially changing the buffers and solvent filters — is essential.

Aqueous cleaning

In the commercial world there are divided opinions about whether it is advisable to use aqueous cleaning for films other than release prints. Concerns involve the high value of camera original and duping materials and the potential hazards of improper drying, such as water marks caused by poor drying or even blocking.

Aqueous cleaning is not as thorough in removing greases and oils as solvent systems. There are other drawbacks, especially concerning the stability of gelatin in decomposing films. There may also be issues regarding the water that has been absorbed into the base during cleaning not being fully removed after drying and acting as a reservoir of water, which contributes to further decomposition.

Rewashing

Rewashing is not the same as cleaning a film, although some cleaning action occurs. Rewashing is designed to reduce surface blemishes such as minor scratching, mould damage and the effects of ferrotyping.

Rewashing is an aqueous based solution that is designed to swell the gelatin used in the emulsion and the backing layer. The degree of swelling of the gelatin is dependant upon pH, (Fig 12.9) which determines the net charge of the gelatin molecule.

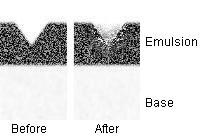

The result of swelling the gelatin is to increase the distance between the gelatin chains. This moves many of the chains surrounding a blemished area closer together. As the gelatin is washed and dried it returns to near its iso electric point and the chains draw in closer together again, recreating many of the intermolecular bonds, 'crosslinking’.

After full drying, the gelatin returns to its original unswollen state. However, the crosslinking has drawn the sides of small blemishes together, effectively reducing the dimensions of the blemish (Fig 12.10).

Formula

| Chemical | Weight (g/100 litre) |

|---|---|

| Sodium polymetaphosphate | 500 |

| Sodium sulfite | 840 |

| Sodium metabisulfite | 1000 |

Considerations

There are several issues that arise with rewashing archival film. These are:

- weakening of the base as it absorbs moisture

- damage to perforations and splices

- brittleness of the base

- solubility of any surface treatments or image dyes

- decomposition leading to acid levels causing increased solubility of the emulsion

To reduce the risk of damage to the film during rewashing, careful examination of the entire film is needed and any damage or splices need to be reinforced or supported (Fig 12.11) with a piece of tape attached to the base. A small amount of overhang will make it easier to remove the tape once the film has been rewashed.

If the film has any decomposition or unknown treatment then test a small, less important section of the film.

The machine used for rewashing needs to be well maintained so that there is no dirt in the system, especially the drier, or unevenness in the transport.

The transport tension on the film is reduced to prevent undue stress on the film, the idea being to provide transport through the machine that is as gentle as possible.

The degree of the reduction in the blemishing in the emulsion is largely dependant upon the severity of the damage. Deep scratches where part of the image has been lost will still be apparent. However, light scratches or other surface blemishes can be made almost unnoticeable.

'Unblocking’ film

On occasion film can adhere to itself with the reel to form a solid mass, known as blocked, that cannot be unwound without causing serious damage to the emulsion, to the base, or both. The film can become blocked by two known mechanisms: high humidity and tight wind and decomposition.

High humidity and tight wind

Blocking caused by high relative humidity and wind tension

Extended periods of high humidity will cause the emulsion to absorb water from the air and swell. If the film is wound tightly then the swollen gelatin will press against the adjacent layer in the film reel. In time the softened gelatin will start to acquire the surface characteristics of the surface it is pressed against. This effect was used in the past to produce highly glossy surfaces on still photographic prints and was known as ferrotyping.

Motion picture films have a topcoat that contains small granules of hardened gelatin that provide a slightly matt surface. This is used as an aid to handling and gives certain light transmitting characteristics. If the swollen gelatin presses against a smooth surface, such as the base of an adjacent layer of film, then this layer is pressed into the emulsion and the emulsion surface takes on a shiny appearance. This will affect the light transmission characteristics and be visible on projection (Fig 12.12). This effect, which is undesirable in motion picture film preservation, is also known as ferrotyping.

Humidity blocking

Under conditions of high humidity and tight wind the gelatin can start to crosslink from the emulsion to the backing layer of the adjacent layer in a reel. This adhesion can form a bond stronger than the bond between the emulsion and the subbing layer.

Consequently if a film is carelessly unwound then the emulsion will tear from the subbing layer. In lesser instances the emulsion may lift away from the subbing layer but then release from the adjacent layer. This leaves a space between the emuslion and the base which causes a blemish that is highly visible. Locally this is referred to as antiferrotyping. An example of this is visible as the thin white line on the image in Figure 12.12 i.

Unblocking humidity induced blocking

Soaking a blocked film in a slightly alkaline solution can reduce the degree of adhesion. The alkaline solution (given in Table 12.3) is around pH 8 which swells the gelatin and creates a negatively charged surface which slightly repels the adjacent gelatin layer.

| Chemical | Weight (g/litre) |

|---|---|

| Sodium polymetaphosphate | 15 |

Table 12.3 Unblocking Solution

The process is very slow and can take many weeks to reach the stage where the film can be unwound without significant damage. During treatment the solution needs to be changed on a daily basis as this prevents too much biological action affecting the film. However, biological action still remains a problem.

While undergoing treatment the film needs to be checked regularly. If some of the film can be unwound, do so and wash and dry it immediately. Identify the sections and splice them together at some later date.

A particular problem is with A and B rolls of 16mm film, where often the black spacing has been spliced in with the spacers, emulsion reversed to the image emulsion. This creates parts of the roll where there is emulsion to emulsion contact, which is often exceedingly hard to unblock without damage.

To unwind the film place it on a spindle while still wet and kept it wet while unwinding carefully (Fig 12.13). Placing the film in an ultrasonic bath can help to release the film. This is a slow and painstaking process that cannot be hurried.

After unblocking, the film needs to be rewashed to reduce any blemishing that may have occurred and to thoroughly remove any treatment chemicals.

Decomposition

Blocked decomposed film

As a film decomposes the acids formed create an environment in the film base polymer that causes the plasticisers that are physically attached to the chains to detach and migrate to the surface of the film base. Some of the plasticisers will move through the emulsion, creating small rupture marks. In extreme cases these will cause large holes to appear in the emulsion. Examples of these holes in the upper left and right corners are shown in Fig 12.16.

While the acid levels are building the gelatin is also being affected, the decrease in pH creating a positively charged surface. Plasticisers are attracted to positive charges and will bond to the charges on the surface of the gelatin, emulsion and backing layer.

The plasticisers also form intermolecular bonds that eventually form a solid layer that is bonded to each of the gelatin layers. This turns the film into a solid blocked mass.

Unblocking decomposed film

Since it is the plasticisers that are creating the adhesion to unblock the film, a solvent that dissolves the plasticisers is required. Selection of a suitable solvent is critical to prevent minimal leaching of the plasticisers that still remain in the film base.

Ethanol is a very effective solvent but will also readily leach any remaining plasticisers from the base. Ethanol also reacts with the acid (acetic and nitric – see note below) with one of the by-products being water. The water produced will substantially soften the emulsion gelatin. To reduce the amount of water produced an approximately two per cent mixture of ethanol and 3M HFE 71-DA is used, the exact concentration needed is established on a case-by-case basis.

To apply the solvent, use a small syringe to drop a small amount of solution at the interface between the layers of film as it is unwound.

The procedure is slow and painstaking and requires a deal of care to prevent damage to the emulsion, which becomes very soft. Fortunately the dissolution of the plasticiser is a fast reaction.

WARNING: ethanol reacts exothermically with nitric acid and generates toxic nitrogen oxides. For this reason ethanol should not be used for unblocking nitrate film.

The National Film and Sound Archive of Australia acknowledges Australia’s Aboriginal and Torres Strait Islander peoples as the Traditional Custodians of the land on which we work and live and gives respect to their Elders both past and present.